At Mountain Fruits (Pvt.) Ltd, our work is more than processing dried fruits — it’s a living example of a climate-conscious business model in action. Operating from Gilgit-Baltistan, a region already witnessing the effects of glacial melt, shifting growing seasons, and water scarcity, we have adopted practices that both mitigate climate risks and support local sustainability.

By sourcing from smallholder farmers who use organic methods, minimizing energy use through sun-drying, avoiding synthetic inputs, and maintaining natural biodiversity, we reduce our environmental impact while empowering communities. Our packaging choices, fair pricing, and soil-friendly farming networks help ensure that agriculture in this region remains resilient under a changing climate

This blog outlines the step-by-step processing methods we use — covering each dried fruit product — and highlights how our practices align with the highest global food and sustainability standards.

Certified to Care: Our Commitment to Quality

At Mountain Fruits, our entire production process is rooted in three guiding certification frameworks:

HACCP (Hazard Analysis and Critical Control Points) ensures food safety through preventive hygiene and process controls. Learn more at https://www.fao.org

Organic certification reflects our chemical-free, pesticide-free approach from orchard to final packaging. Learn more at https://www.ifoam.bio.

Fairtrade certification affirms our commitment to ethical sourcing, fair farmer compensation, and transparent trade. Learn more at https://www.fairtrade.net/.

Every step we take — from fruit collection to export — is shaped by these standards

From Orchard to Export: Our Dried Fruit Processing Steps

Raw Material Collection and Sorting

We begin our journey by sourcing high-quality raw fruits and nuts directly from smallholder farmers in the fertile valleys of Hunza and Ghizer District. Upon arrival at our processing facility, the produce is carefully inspected. We manually sort the fruits and nuts to remove any material that doesn’t meet our quality benchmarks. Only healthy, mature, and clean products proceed to the next stage. This initial sorting phase also fulfills our Organic and Fairtrade traceability requirements, ensuring that every batch is linked back to its source. Almonds, for example, are packed with protein, vitamin E, and Magnesium — making them a heart-healthy snack even before they’re processed.

Washing and Cleaning

The next step is gentle cleaning. Apricots and cherries are thoroughly washed with clean water to remove dust and surface contaminants. Almonds and kernels are sieved using a sieving machine to remove the unwanted powder they contain. No chemicals, preservatives, or artificial waxes are used — fully complying with Organic food handling protocols. Sweet apricot kernels at this stage maintain their content of vitamin B17 and healthy oils.

Natural Drying and Dehydration

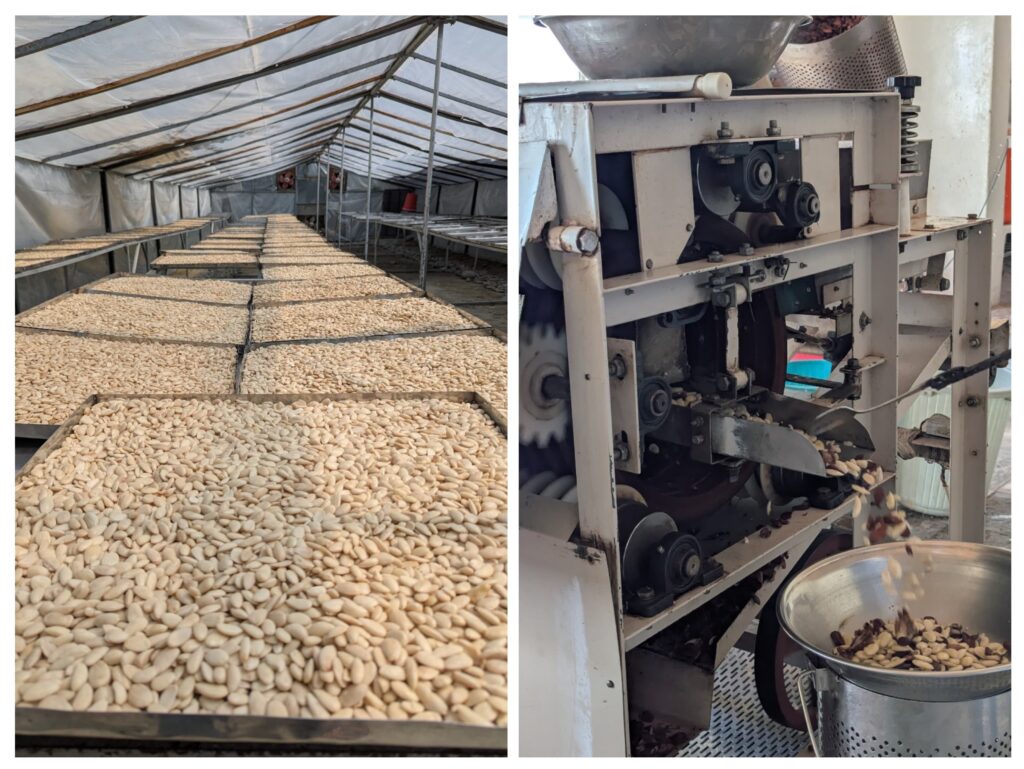

After cleaning, the drying process begins. We use traditional sun-drying methods and solar-assisted drying systems to ensure the fruits retain their natural flavor, color, and nutrients. Apricots and cherries are laid out in trays and dried under sunlight, while almonds and kernels are air-cured in shaded, ventilated spaces, the end product maintains its organic integrity and nutrient profile. Dried apricots are a great source of potassium, fiber, and iron, while dried cherries are known for their antioxidants and anti-inflammatory benefits.

Blanching of Almonds

For blanched almonds, we carry out a certified HACCP-controlled process. Raw almonds are soaked in hot water for a short period to loosen the skins. Once softened, the almonds pass through mechanical rollers that gently remove the skins without damaging the kernels. The blanched almonds are then air-dried under controlled conditions to remove surface moisture. This step requires careful handling to prevent contamination and maintain food safety standards throughout. Blanched almonds retain their high vitamin E content and become easier to digest for sensitive consumers.

Screw Press Oil Extraction

For almond and apricot kernel oil, we use screw press oil extraction machines, In this process, cleaned sweet kernels or almonds are fed into a mechanical screw press, which crushes and compresses them to extract oil at controlled pressure and moderate temperature. This method allows us to preserve the natural aroma and beneficial properties of the oil while ensuring food-grade quality. No refining chemicals or solvents are used. The extracted oil is filtered and stored in food-safe containers for export or further packaging. Both almond oil and apricot kernel oil are rich in unsaturated fats and vitamin E, making them valuable for culinary and skincare use.

Grading and Quality Assurance

Once the fruit and nut processing is complete, we begin a meticulous grading process. Each product is classified by size, and appearance. We check for color consistency, absence of physical defects, and any potential contaminants. Our quality assurance team uses calibrated moisture meters, batch tracking, and sampling protocols to meet the strict requirements of HACCP, Organic, and Fairtrade audits. Each batch is documented, traceable, and verified before approval.

Packaging and Labeling

Unlike companies that produce snacks or value-added bars, we remain committed to simple, bulk exports. All of our dried fruits and nuts are packed into 10,11 or 12-kilogram food-grade cartons according to the product, sealed in a hygienic environment. Each box is labeled with essential information including batch number, product name, origin, net weight, and certification logos. Our packaging process follows strict hygiene protocols: gloved, uniformed staff work in a sanitized, food-safe facility under regular supervision.

Safe Storage and Global Export After packaging, the products are stored in temperature- and humidity-controlled environments. Storage areas are monitored for pests, airflow, and contamination risks. When ready for export, each shipment is backed by complete documentation — including Organic and Fairtrade certificates, shipping records, and HACCP compliance logs. We serve a growing number of clients across Europe who value safe, ethically produced dried fruits from Pakistan’s northern regions

Why Our Method Matters?

Our processing method is not just about getting dried fruits to the market — it’s about doing it right. By upholding Organic integrity, Fairtrade values, and HACCP standards, we ensure food safety, environmental stewardship, and social responsibility in every box we ship.

We believe that every apricot, almond, and kernel we export tells a story — of clean farming, careful processing, and a commitment to a better food future.

Final Thought

At Mountain Fruits (Pvt.) Ltd., we don’t just sell dried fruits — we deliver trust, quality, and ethical sourcing. Our methods are simple, sustainable, and deeply rooted in the traditions of Gilgit-Baltistan, shaped by global standards and local pride.